Forced Bed Aeration (FBA™)

Aerated wetland (Forced bed aeration - FBA™) is an innovative technology composed of one or more constructed wetland beds (either horizontal or vertical), fully saturated and equipped with an aeration system (blower). The forced air within the bed optimizes the oxidation removal processes occurring within constructed wetlands, allowing an areal footprint reduction of 4-5 times in comparison to classical constructed wetlands. Energy consumption remains low, estimated as 5 times lower in comparison to conventional biological reactors (activated sludge). The FBA™ is patented by S.D. Wallace, among the maximum worldwide experts of constructed wetlands, and is exclusively proposed by IRIDRA in Italy.

Aerated wetlands were introduced 15 years ago in the US by Scott D. Wallace, one of the most relevant experts on treatment wetland worldwide. One of the most diffused aerated wetland technology is the one patented with the name Forced Bed Aeration (FBA™), for which IRIDRA has the exclusive in Italy.

A technology for complex wastewater

Examples of complex wastewater successfully treated with aerated wetlands are:

- wastewater contaminated with the hydrocarbon (usually produced by refineries or found in contaminated sites)

- airport stormwater runoff contaminated by deicing products

- groundwater to be remediated from contamination

- mining wastewater

- wastewater with high organic loads (e.g., wineries or dairies) or high ammonia loads (e.g. swine wastewater).

Less areal footprint

Aerated wetlands are also a valuable technology for urban wastewater. Indeed, the use of aerated wetlands reduces up to 4-5 times the requested implementation area in comparison to conventionally constructed wetlands.

Low energy consumption

The introduction of aeration requires an additional input of energy in comparison to conventional constructed wetlands. On the other hands, the energy consumption remains at least 5 times less in comparison to conventional technological solutions (e.g. activated sludge systems). The use of inverter and PLC permit the regulation of oxygen transfer, optimizing energy consumption.

From passive to active regulation

Despite conventional constructed wetlands, which are passive treatment technologies with minimal possibility of regulation, aerated systems give the possibility to better regulate the treatment processes through the regulation of oxygen transfer. However, operational and maintenance activities remain simple, maintaining the well-known advantages of nature-based solutions.

Refurbishment

FBA™ is also well suited for the refurbish of undersized treatment wetland as well as for treatment wetland plant facing an increase in influent wastewater loads. Indeed, the aeration system can be added to an existing wetland plant without the removal of filling media, thanks to the use of a proper equipment.

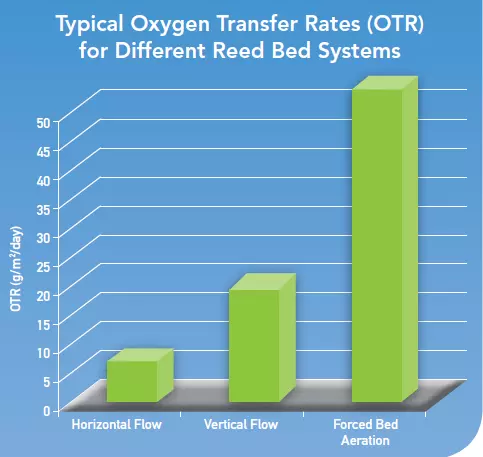

Comparison of oxygen transfer rates between conventional and FBA™ wetland solutions.

FBA™ constructed wetland for the treatment of the combined sewer overflow upstream the WWTP of Merone (CO), designed by IRIDRA in collaboration with Rietland (D. Van Oirschot) and NaturallyWallace (D. Scott Wallace). First aerated wetland for treatment of combined sewer overflow in Italy and among the first worldwide.