Advanced numerical modelling

Advanced numerical process-based models aim to simulate different physical, biochemical, and physiological processes occurring into constructed wetlands. Despite their complexity, process-based models are promising tools to design constructed wetlands facing variable influent organic loads.

IRIDRA is starting to use advanced numerical models (e.g. HYDRUS) for the design of constructed wetland wastewater treatment plants under particular functioning conditions, such as time-variable influent loads (e.g., wineries, combined sewer overflows). In this way, IRIDRA guarantees to its clients the use of the most advanced theoretical tools for a better design of constructed wetland treatment plants.

Nowadays, constructed wetlands (CWs) are designed with either rule of thumbs (e.g., square meter per PE) or with first-order kinetics fitted on large databases. Therefore, CWs are considered as "black boxes", treating influent wastewater according to the required water quality target. Although the removal processes occurring in a CW are well-known, their quantification within CW design phase is usually neglected.

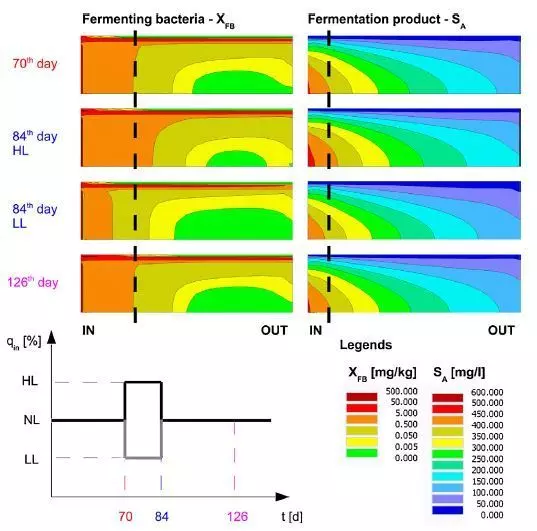

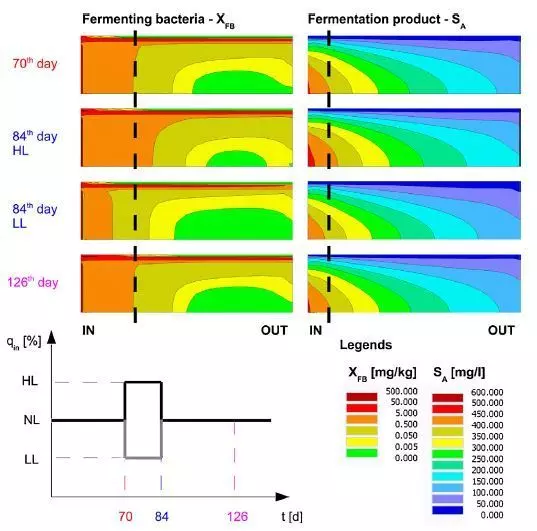

The aim of process-based models is to quantitatively simulate the different contribution of physical, biochemical and physiological removal processes occurring in a CW treatment plant (Langergraber 2008; Meyer et al., 2015). In this way, it is possible to better understand some important behaviour of a CW, such as bacteria distribution, clogging formation and propagation or the response to time variable loads (Samsó and Garcia, 2013,2014; Rizzo et al., 2014, 2016).

Up to now, the process-based model complexity has hindered their use in the design phase, in spite of the advantages as shown, for instance, by Palfy et al. (2015). Nevertheless, advanced numerical modelling simulation can be a valuable tool to better design CW system working in peculiar conditions, such as working under variable conditions as those serving wineries or treating combined sewer overflow.

IRIDRA' experience

IRIDRA's staff has the required knowledge to use advanced process-based models (e.g. HYDRUS, BIO_PORE) in the design phase, improving the overall CW design. Moreover, IRIDRA collaborates with among the most important international research institutes, in order to improve process-based models and reduce the gap between the theoretical and practical application of process-based models.

Response of fermenting bacteria and different acetate spatial distribution of a horizontal flow CW pilot plant facing a sudden influent load change, simulated with the HYDRUS model

Modelling of time variable effluent flow rate (left) and moisture content (right) of the first vertical flow stage treating the combined sewer overflow upstream the WWTP of Carimate (CO), designed by IRIDRA