Constructed Wetlands for agro-food industries

Agro-food industries - IRIDRA's solutions

Classical constructed wetlands

- Constructed wetlands with horizontal subsurface flow (HF)

- Hybrid constructed wetlands (HF + VF + HF, HF + VF + FWS, HF + FWS, HF + VF + HF + FWS)

Intensified constructed wetlands (Constructed wetlands 2.0)

- French reed bed (FRB)

- Aerated constructed wetlands (FBA™)

Additional integrated solutions

- Sludge drying reed bed (SDRB)

Wastewater produced by agro-alimentary activities are often characterized by a high content of organic matter, grease and nutrients (nitrogen and phosphorus) and sometimes by high salinity, and by strong seasonal fluctuations in term of quantity and chemical-physical characteristics.

Because of this, its depuration treatment requests particular attention and accurate evaluation of every technical solution available. As one of the most successful application it can be noted the winery industry: in Italy this sector consists in many hundreds of small producers, whose scarce production and relatively low annual budgets don't allow to choose advanced technological treatments for the depuration of wastewater, so creating big problems in respect of the most recent laws concerning industrial wastewater (law n. 152/99). Constructed wetland (CW) offers an effective solution with low costs of realization and management and low energy consumption.

Constructed wetland removal efficiencies

IRIDRA has designed among the first and most relevant CWs for the treatment of wastewater from agri-food industries in Italy, following also the monitoring phases. Regarding wineries, IRIDRA was worldwide the first firm that designed and supervised the construction of a CW for a winery at full scale. The CW treatment plants serving the wineries of Cecchi, Ornellaia and Zari are in operation since 2001 and were monitored in collaboration with ARPAT. CW systems for winery wastewater treatment shown high organic removal efficiencies with hydraulic retention times of 3-4 days: COD 87-98%, BOD5 92-98%, Suspend Solids 70-90%, Total Nitrogen 50-90%, Total Phosphorous 20-60%. These ranges were confirmed by following research studies (Rochard et al., 2002, Müller et al., 2002, Zanieri et al, 2010, Masi et al 2015).

IRIDRA's experience

IRIDRA still maintains its leadership in the field of nature-based solutions for wineries, continue to propose and monitor novel CW techniques for his particular application (e.g., french systems for raw wastewater, aerated wetlands, or sludge drying reed beds).

One example is the CW serving the winery Cecchi&Sons sited in Castellina in Chianti, which currently treats about 100 m3/d produced by bottling activities and by offices. The CW has the following scheme: 1st stage FRB, 2nd stage HF, 3rd stage FWS. The CW WWTP respects the water quality standard set by Italian law for industrial wastewater.

Another relevant example is the CW WWTP of Ornellaia winery, sited in Bolgheri and currently treating about 40 m3/d of winery wastewater produced by vintage and bottling. The WWTP is a hybrid multi-stage CW, respecting the water quality standard set by Italian law for discharge in the water body.

IRIDRA had also successful applications with dairy wastewater treatment. One example is the CW WWTP for the Fattoria della Piana dairy, which treats about 100 m3/d of dairy wastewater, discharging in the water body.

Val delle Rose winery, Grosseto (GR - Italy)

Treated person equivalent . 1667 PE (referred to organic load)

Chosen Nature-based solution : FRB + HF + FWS

Produced wine : Poggio al Leone, Morellino di Scansano, Litorale

Year of realization : 2012

Cecchi and Sons winery, Castellina in Chianti (SI - Italy)

Treated person equivalent : 1900 PE (referred to organic load)

Chosen Nature-based solution : FRB + HF + FWS

Produced wine : Chianti, Vernaccia di San Gimignano

Year of realization : 2009 (upgrading)

Ornellaia and Masseto Sarl winery, Castagneto Carducci (LI - Italy)

Treated person equivalent : 904 PE (referred to organic load)

Chosen Nature-based solution : HF + VF + HF + FWS

Produced wine : Ornellaia, Masseto, Serre nuove, etc.

Year of realization : 2001

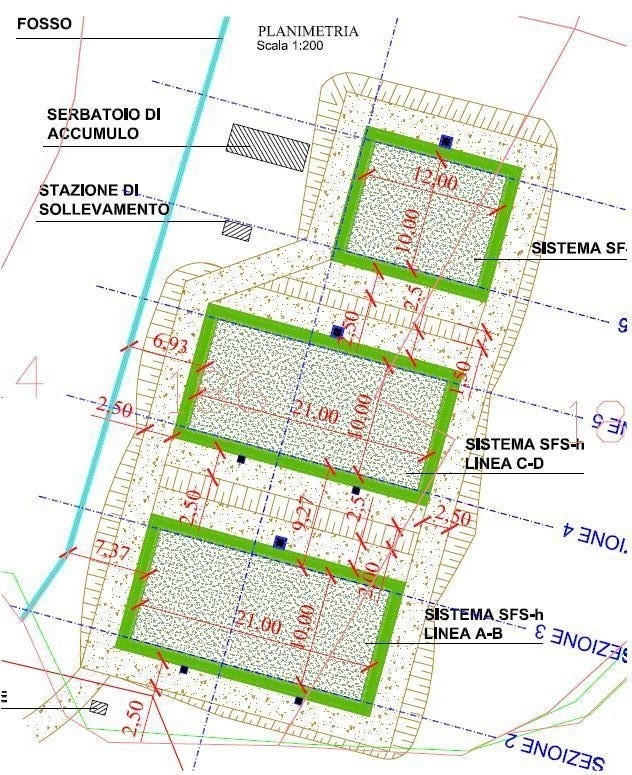

Cantina dell'Agricola Villa Cerna winery, Castellina in Chianti (SI - Italy)

Treated person equivalent : 1333 PE (referred to organic load)

Chosen Nature-based solution : FRB + HF

Produced wine : Chianti Classico, Chianti Classico Riserva

Year of realization : 2019

Il sistema scelto è ibrido multistadio, e segue l'approccio così detto alla Francese per il trattamento dei reflui grezzi. Non è, difatti, presente un sistema primario con fosso settica, ma solo un grigliatura preliminare. Il primo stadio alla francese (French Reed Bed - FRB) da 500 mq, riceve quindi il refluo grezzo, formando sulla superficie uno strato di fango, costantemente tenuto in condizioni aerobiche (quindi senza diffusione di cattivi odori). In tal modo i costi di gestione e manutenzione risultano ancora minori rispetto alle classiche soluzioni di fitodepurazione. L'effluente è poi trattato in un secondo stadio a flusso orizzontale (HF) da 600 mq. Lo schema è lo stesso adottato con successo presso la cantina Cecchi, sempre in Castellina in Chianti, in operazione dal 2009.

L'impianto permetterà lo scarico in acque superficiali in accordo alla normativa Nazionale e Regionale.

Badia of Morrona winery, Terricciola (PI - Italy)

Treated person equivalent : 923 PE (referred to organic load)

Chosen Nature-based solution : HF + VF

Produced wine : Felciaio IGT (Vermentino), Paretaio IGT (Chianti)

Year of realization : 2013

Brancaia in Maremma winery, Grosseto (GR - Italy)

Treated person equivalent : 625 PE (referred to organic load)

Chosen Nature-based solution : HF

Produced wine : Brancaia IL BLU IGT, Brancaia ILATRAIA IGT, etc.

Year of realization : 2012

Caccia al Piano 1868 winery, Castagneto Carducci (LI - Italy)

Treated person equivalent : 313 PE (referred to organic load)

Chosen Nature-based solution : HF

Produced wine : Ruit Hora, Levia Gravia (Berlucchi)

Year of realization : 2013

Carpineto winery, Chianciano Terme (SI - Italy)

Treated person equivalent : 1238 PE (referred to organic load)

Chosen Nature-based solution : HF

Produced wine : Dogajolo I.G.T.

Year of design : 2015

Winery of "La Solatia" delle Tenute Ruffino Srl, Monteriggioni (SI - Italy)

Treated person equivalent : 283 PE (referred to organic load)

Chosen Nature-based solution : HF + VF + FWS

Produced wine : Chianti, Vernaccia di San Gimignano

Year of realization : 2017

A multistage hydrid system was adopted in order to allow the discharge on soil and possible reuse of treated wastewater: (i) 1st stage, horizontal subsurface flow system (HF); (ii) 2nd stage, vertical subsurface flow system (VF); (iii) 3rd stage, a mixed free water surface and pond system to polish and accumulate the wastewater.

The 1st HF stage is planned to be doubled in case of future expansion of the winery.

Winery in Podere Fabbrica district, Pienza (SI - Italy)

Treated person equivalent : 93 PE (referred to organic load)

Chosen Nature-based solution : HF

Year of design : 2016

A. Agr. G.D. Vaijra winery, Barolo (CN - Italy)

Treated person equivalent : 615 PE (referred to organic load)

Chosen Nature-based solution : HF

Produced wine : Barolo Albe®, Langhe Nebbiolo, Barbera d’Alba, etc.

Year of realization : 2013

A multistage hydrid system was adopted in order to allow the discharge on soil and possible reuse of treated wastewater: (i) 1st stage, horizontal subsurface flow system (HF); (ii) 2nd stage, vertical subsurface flow system (VF); (iii) 3rd stage, a mixed free water surface and pond system to polish and accumulate the wastewater.

The 1st HF stage is planned to be doubled in case of future expansion of the winery.

Winery of Casorzo (AT - Italy)

Produced wine : 30,000 ql. of produced wine per year

Chosen Nature-based solution : HF + FWS

Year of realization : 2004

Castlet winery, Costigliole d'Asti (AT - Italy)

Treated person equivalent : 430 PE (referred to organic load)

Chosen Nature-based solution : HF

Year of realization : 2013

Soc. Agr. delle Tenute Ruffino S.r.l. winery, Castellina in Chianti (SI - Italy)

Treated person equivalent : 769 PE (referred to organic load)

Chosen Nature-based solution : lagunaggio + FBA™

Year of design : 2017

Soc. Agr. delle Tenute Ruffino S.r.l. winery, Montalcino (SI - Italy)

Treated person equivalent : 77 PE (referred to organic load)

Chosen Nature-based solution : HF

Year of design : 2014

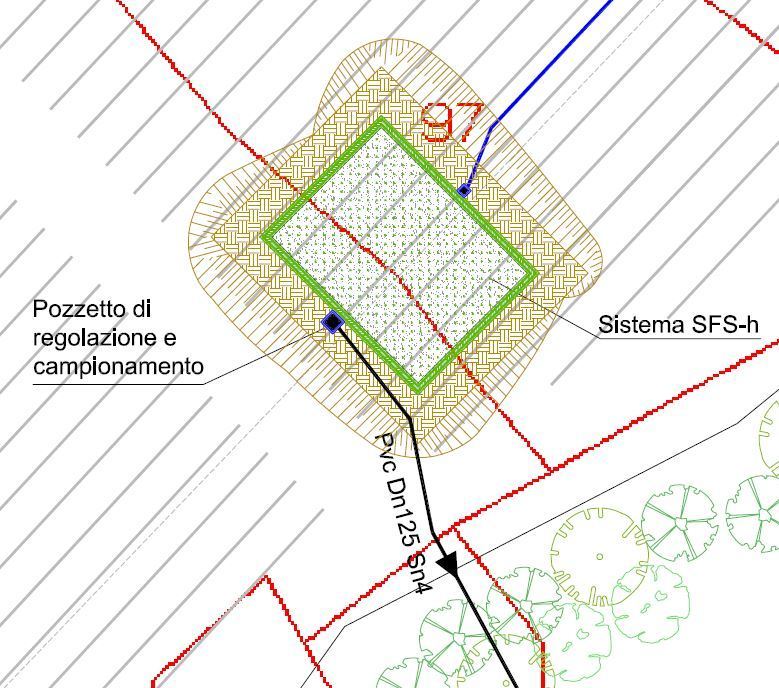

Cantina Bindella Srl Società Agricola winery, Montepulciano (SI - Italy)

Treated person equivalent : 323 PE (referred to organic load)

Chosen Nature-based solution : HF

Year of design : 2017

To treat the wastewater according to Italian law, the Bindella winery installed a HF CW of 520 mq, designed by IRIDRA.

The HF CW treatment plant is under construction.

Dairy of coop. Fattoria della Piana Soc. Agr., Candinoni (RC - Italy)

Treated person equivalent : 1500 PE (referred to organic load)

Chosen Nature-based solution : HF

Year of realization : 2011

Dairy in Kandy (Sri Lanka)

Treated person equivalent : 65 PE (referred to organic load)

Chosen Nature-based solution : HF

Year of realization : 2012

Dairy of Soc. Agr. La Marchesa S.r.l., Lavello (PZ - Italy)

Treated person equivalent : 770 PE (referred to organic load)

Chosen Nature-based solution : HF + VF

Year of realization : 2014

Dairy of Coop. Agricola Poggio Antico s.r.l., Montespertoli (FI - Italy)

Treated person equivalent : 20 PE (referred to organic load)

Chosen Nature-based solution : HF

Year of realization : 1998